CASE STUDY: Cyclife Sweden AB

Control over hours and a better utilisation rate with an integrated platform

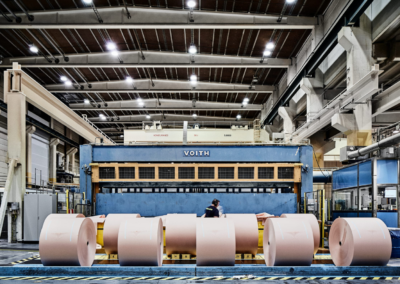

Cyclife Sweden AB handles and volume-reduces low-level radioactive waste (metal, liquids, combustible waste and radiation sources) for companies within the nuclear power industry and other industries – with customers in both Sweden and Europe.

Cyclife Sweden is a part of EDF Groupe (Électricité de France), one of the world’s largest energy companies, partly owned by the French State.

Cyclife Sweden has 100 salaried workers and a number of hourly-paid employees at the waste facilities in Studsvik, just outside of Nyköping.

“For Cyclife, the benefits of having a fully digitalised platform and integration to various business systems such as SAP and payroll – without human intervention and paperwork – are great. With exact job and project hours, we can provide our customers with offers that correspond to the actual production time”.

– Urban Lind, IT Manager, Cyclife

The challenge

- ^Too many manual processes related to time reporting and absence management

- ^Insufficient overview of use of time on external projects for follow-up

- ^Insufficient overview of the production chain to be able to make the right scheduling, planning and follow-up

Success criteria

- ^An integrated solution for both production and project reporting as well as payroll-related data

- ^A solution that covers all salaried workers and hourly-paid employees in the Swedish part of the company

- ^All employees have a mobile phone for all reporting – even in production

Key functionality

- ^ProMark 365 Cloud Individual with Time & Attendance reporting

- ^Job and project registration

- ^Registration via mobile app and terminals

- ^Integration with SAP Business One and Visma Agda PS payroll system

- ^SuperuserService from ProMark

Outcomes

- ^Simpler payroll process, without manual work

- ^Managers have overview of employees’ attendance and absence, which simplifies working time scheduling

- ^Collection of hours per job and project provides overview of production time and all internal working time for follow-up and forecasting

Primary results

- ^Correct salary on time

- ^Optimised scheduling with control of working hours and overtime limits

- ^Exact job and project hours contribute to a better utilisation rate

- ^Predictable costs in the IT budget

Talk to our experts

Learn how ProMark can help you optimise your workforce, improve productivity and generate savings. Schedule a demo or call sales to get an introduction.

Discover more

Our latest cases