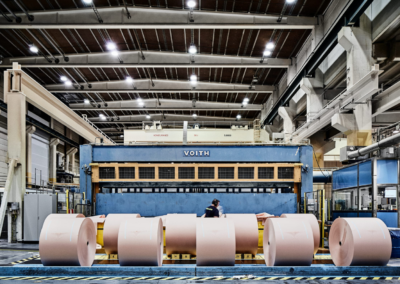

CASE STUDY: SM Industries A/S

Correct data for follow-up on production hours

SM Industries A/S manufactures and co-engineers heavy complex steel structures for a diverse range of industries, including wind energy, offshore oil and gas, transmission towers and material handling systems.

Operations are based on a dual production strategy with both series and order production. SM Industries A/S has two advanced and highly automated production plants located near Aabenraa harbour in the southern part of Denmark.

SM Industries A/S is owned by Euro-steel, has approx. 600 employees in Denmark and a revenue of 664 million DKK in 2017.

“With ProMark, we now have a modern, automated solution for collection of employee working time. It has provided us with the desired transparency so we can constantly track use of time and status on production orders – and adjust if necessary”.

– Bo Bendixen, CFO, SM Industries A/S

The challenge

- ^Too many manual processes related to the collection of employee working time and absence

- ^Hard to figure out data

- ^Not possible to track status on orders and use of time

Success criteria

- ^Complete solution covering approx. 500 hourly-paid employees and 100 salaried workers

- ^All hourly-paid employees must clock in and out and register job time, whereas the salaried workers only need to register absence

- ^Staff roster planning solution to manage multiple shifts

- ^Roll-out in phases

Key functionality

- ^Time & attendance and absence registration

- ^Job registration

- ^Registrations via terminals, PC and mobile app

- ^Web-based staff roster planning

- ^Integration with ERP, production and payroll system

- ^Reporting and Business Intelligence

Outcomes

- ^Automated solution with smooth approval of registrations

- ^Increased transparency in job data for managing capacity and progress of orders

- ^Ability to push information on orders to the employees so they can follow status and use of time

- ^Modern, future-proof solution

Primary results

- ^Fast and current registration of working hours

- ^Reduced administrative time

- ^More efficient scheduling of working time

- ^Data in real-time for correct and complete follow-up on all production hours

Talk to our experts

Learn how ProMark can help you optimise your workforce, improve productivity and generate savings. Schedule a demo or call sales to get an introduction.

Discover more

Our latest cases