CASE STUDY: Kverneland Group Kerteminde

High power management information

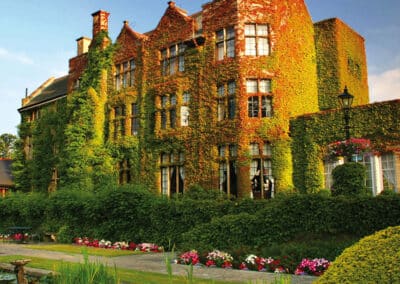

Experience, competence and quality are the characteristics of the plant in Kerteminde which is the Centre of Excellence for grass equipment in the Kverneland Group.

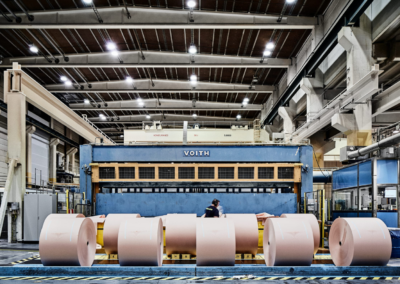

With 50,000 square metres under roof, the plant in Kerteminde is the largest in the Kverneland group, producing equipment for the cultivation of grass such as equipment for forage, bale and feeding equipment. In recent years, the Kverneland Group has made large investments to increase capacity, flexibility and quality control.

One investment is ProMark Business Intelligence which gives management an improved decision support through tailored data reporting.

The challenge

- ^Lack of tools for accurate analysis of absence

- ^Complicated bonus calculations require simplified procedures

- ^Need for accurate data for decision-making

Success criteria

- ^The solution covers 350 employees, both in production and administration

- ^The solution will ease administration and provide accurate and customised reports

Key functionality

- ^Time & Attendance registration

- ^Job registration

- ^Business Intelligence for analysis and reporting

- ^Terminals for T&A and shop floor registration

- ^Integration to SAP ERP and EPOS Payroll

Outcomes

- ^Overview over: Reasons for absence, absence of different employee types, departments and periods

- ^Ability to analyse both on time, efficiency, quantity and material consumption as well as scrap reasons in the production

- ^Data is used as active decision support available in relation to needs and situation

Primary results

- ^ProMark is a major contributing factor to motivated and productive employees, high quality and great delivery compliance

Talk to our experts

Learn how ProMark can help you optimise your workforce, improve productivity and generate savings. Schedule a demo or call sales to get an introduction.

Discover more

Our latest cases